Vacuum forming is a foundational process in the world of plastics manufacturing, used in everything from packaging to automotive parts. At Gobelovac, we specialize in custom vacuum forming machines designed for durability, precision, and efficiency. In this article, we’ll walk you through how vacuum forming works and provide a detailed explanation of a vacuum forming machine diagram to help you visualize every component of the process.

What Is Vacuum Forming?

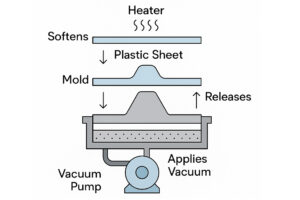

Vacuum forming is a thermoforming process that involves heating a plastic sheet until it’s pliable, then shaping it over a mold using vacuum pressure. Once cooled, the formed plastic retains the mold’s shape, creating a precise and consistent product.

This technique is widely used due to its cost-effectiveness, speed, and ability to produce high-quality plastic components in both small and large volumes.

Why Understanding the Vacuum Forming Machine Diagram Matters

Whether you’re a machine operator, engineer, or product designer, understanding a vacuum forming machine diagram can help you:

- Troubleshoot issues more effectively

- Optimize production settings

- Understand how different machine components interact

- Select the right machine configuration for your needs

Let’s break down the vacuum forming process and machine components step-by-step.

How Vacuum Forming Works: Step-by-Step Process

- Clamping – A plastic sheet is clamped securely in place to prevent movement during the heating and forming process.

- Heating – The sheet is moved under a heater, where it’s softened until it reaches its forming temperature.

- Forming – Once heated, the sheet is lowered over a mold, and a vacuum is applied. This removes air between the sheet and mold, causing the plastic to conform tightly to the mold’s shape.

- Cooling – The formed plastic is cooled and hardened in place.

- Release and Trim – The part is released from the mold and excess material is trimmed off.

You can see this process clearly illustrated in our machine development process video.

Detailed Vacuum Forming Machine Diagram Breakdown

Each vacuum forming machine includes several essential components. Here’s a closer look at each one as seen in a vacuum forming machine diagram:

- Clamp Frame – The clamp frame holds the plastic sheet in place during heating and forming. It needs to be strong enough to keep the material flat and secure as it becomes more pliable under heat.

- Heating Element – Located above the plastic sheet, the heating unit warms the material evenly to its forming temperature. At Gobelovac, our machines feature efficient, customizable heating zones for different material types and thicknesses.

- Vacuum Plenum – This is the chamber beneath the mold that creates suction. When vacuum pressure is applied, air is evacuated from the space between the mold and the plastic, forcing the sheet to conform to the mold’s surface.

- Mold Table (Platen) – This platform holds the mold itself. It can be stationary or movable depending on the machine’s configuration.

- Cooling Fans or Spray Systems – Cooling elements help set the plastic quickly to maintain precise mold definition. These components are essential in high-volume production to reduce cycle times.

- Control Panel – This is the operator’s interface for adjusting temperature, vacuum pressure, cycle timing, and more. Gobelovac machines offer intuitive touch screen controls for optimal usability.

Advantages of Understanding Your Vacuum Forming Machine Diagram

- Enhanced Efficiency: Knowing each component helps you fine-tune performance and minimize material waste.

- Reduced Downtime: Troubleshooting becomes quicker when you understand the layout and function of each part.

- Improved Product Quality: Proper temperature, vacuum, and timing settings mean sharper detail and better consistency.

Choosing the Right Machine for Your Needs

At Gobelovac, we offer a wide range of custom vacuum forming solutions to suit industries such as automotive, aerospace, medical, and consumer goods. If you’re unsure which machine configuration or model suits your production line, our team can design and build the perfect fit based on your exact specs.

Final Thoughts: Vacuum Forming Machine Diagrams Aren’t Just Blueprints – They’re Roadmaps

A vacuum forming machine diagram is more than just a technical illustration-, it’s a key to understanding your manufacturing process. From improving your operational efficiency to ensuring better product quality, knowing how each machine component works together can give you a serious production edge.

Need help selecting the right machine or understanding your system’s layout? Contact us today and we’re here to help you every step of the way.