Optimizing Plastic Drying: Choosing the Right Drying Oven & Ideal Temperature Settings

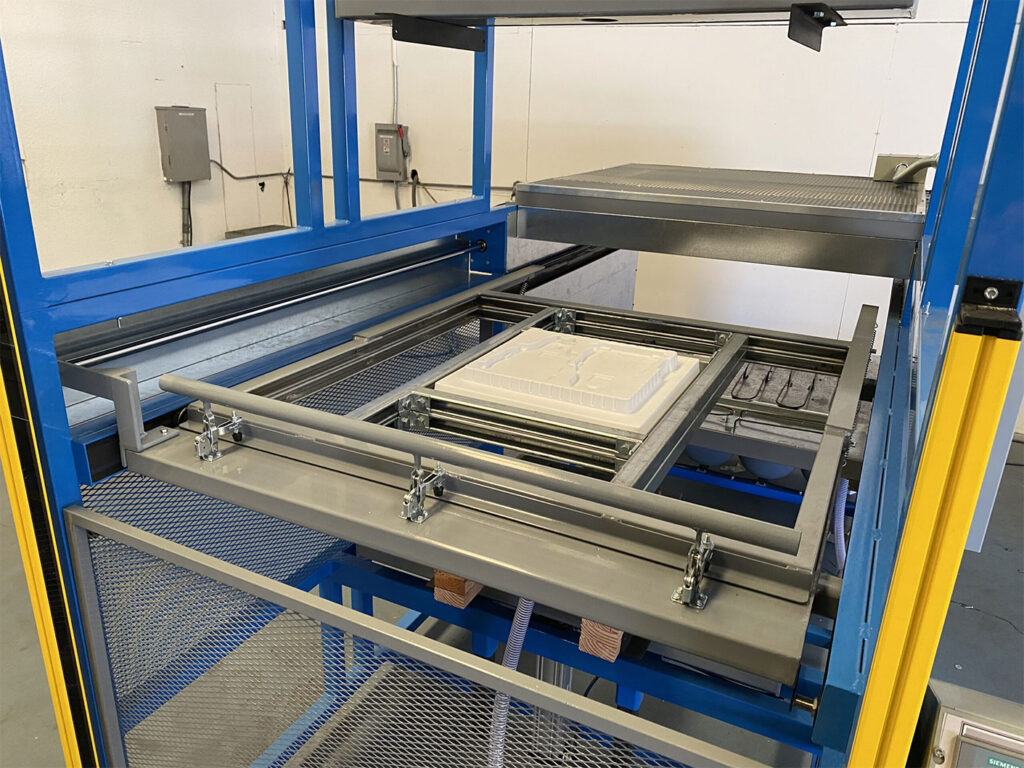

Ensuring that plastic sheets are properly dried before processing is a critical step in achieving high-quality vacuum-formed products. Many plastics, especially hygroscopic materials like PET, ABS, and polycarbonate, absorb moisture from the air. If this moisture isn’t removed, it can cause defects such as warping, bubbling, and reduced structural integrity.In industrial applications, moisture contamination can […]

Optimizing Plastic Drying: Choosing the Right Drying Oven & Ideal Temperature Settings Read More »