How Large-Scale Vacuum Forming Transforms Industrial Manufacturing

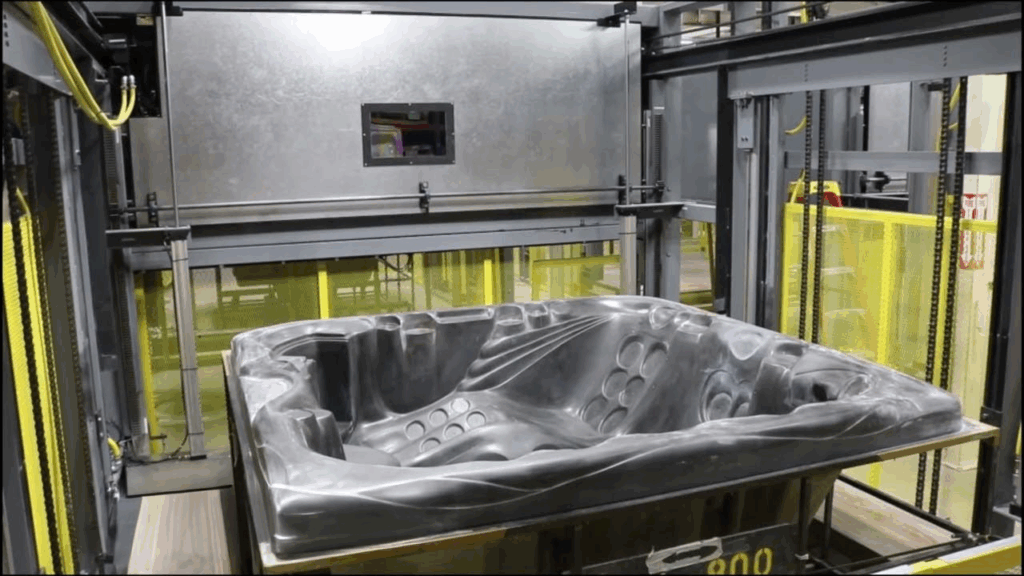

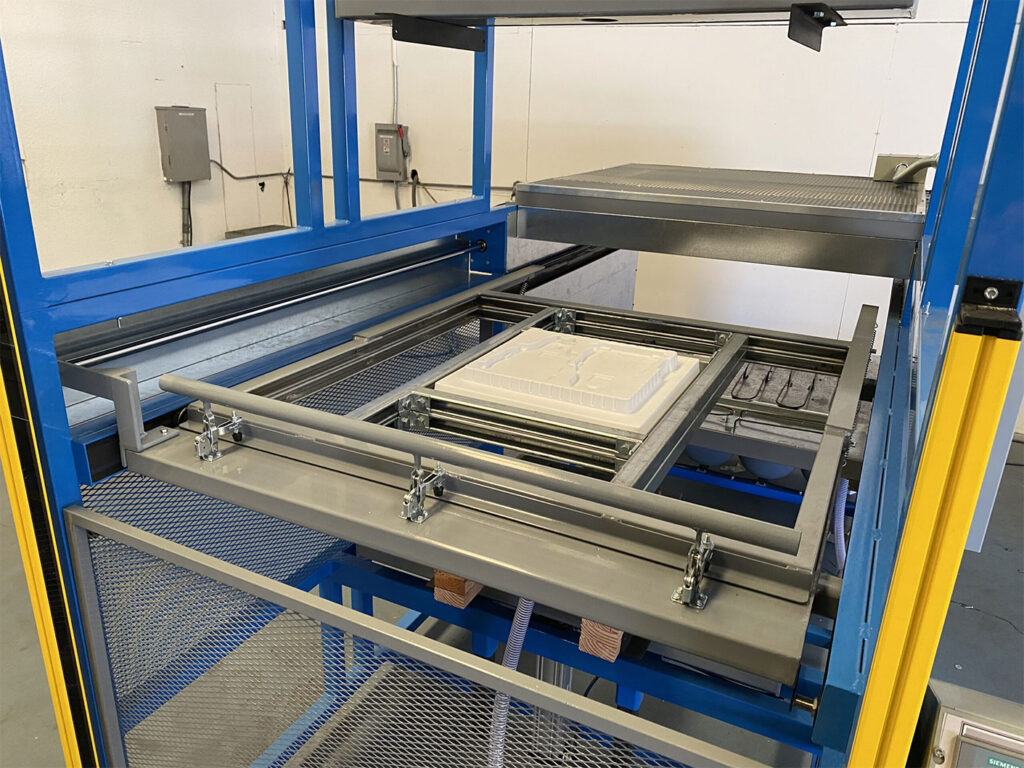

Manufacturing operations depend on production methods that deliver speed, accuracy, and predictable output. Large-scale industrial vacuum forming machines provide these advantages by heating thermoplastic sheets to a pliable state and shaping them over molds using vacuum pressure. This process produces durable components used across multiple sectors, including automotive panels, protective packaging, medical enclosures, and consumer […]

How Large-Scale Vacuum Forming Transforms Industrial Manufacturing Read More »